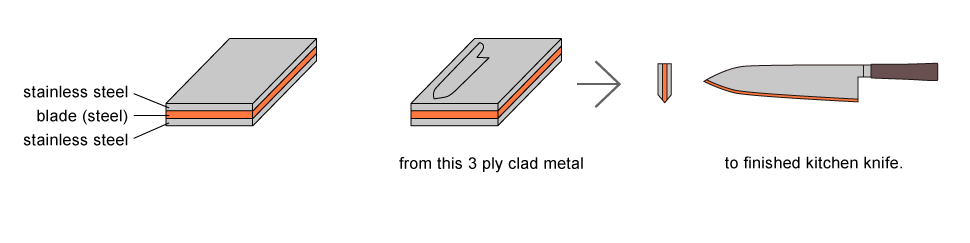

We produce laminated metal sheets (roll -bonding different types of metal).

Takefu Special Steel takes pride in being one of the original steel makers in Japan, to widely supply original steel products for knives (from household use to industrial machinery), industrial blade steels, and craft material.

Cladding is the manufacturing process whereby two or more metal sheets are joined together, either from edge to edge (fully clad) or embedded (partially clad).

This is fundamentally different from metal plating and gluing.

The metal cladding process enables a synergy of combined properties, greater than the sum of properties of the individual component metals, achieving a final product. We call this "composite property"

The steels made by this process are as difficult to bend or break as a Japanese KATANA (Samurai sword) because the hard steel core is covered by soft metal.

Easy processingClad steel is easy to process, to forge and grind (edging and polishing).

Corrosion resistantUsing the correct material combination enables improved corrosion resistance (corrosion resistance differentiation).

Improved wear resistance and edge retentionThe blade steel component is worked to a fine structure by the forging press, in order to improve the wear resistance and edge retention.

Material savingThere is material cost saving realized by only using high-quality blade steel where necessary.

Easy to straightenThe steel is difficult to split and crack, yet easy to straighten after bonding with soft metal.

Drilling holes and welding after heatIt is possible to drill holes in the steel and weld it after it has been quenched hardening.

Improve designThe clad steel has the appearance of a multi-layer or waved "HAMON" pattern visible in the area where the cutting edge joins the different multi layered steel.