Measured at 200mm² test specimen surface

Test conditions: 5% sodium chloride solution, 35°C, 75kPa, 24h continuous spray

SPG STRIX was born from the proposition to develop a “blade-oriented powdered steel” that can achieve optimum performance when used as a cutting tool.

While we have heard that conventional hard powder steels with a hardness of about HV900 (HRC67) are difficult to sharpen on a grinding wheel, we have not heard of many such cases with carbon steels of the same hardness.

Although the hardness is the same, the ease of sharpening is different. Why is there such a difference?

The answer is that blade steel hardness is the combination of the "hardness of the metal base" and the "hardness of the metal carbides".

SPG STRIX is a stainless powder steel that was created to strengthen a metallic base material, featuring both workability and ease of sharpening like carbon steel, despite its high hardness.

It is the best powder steel for knives, as its strong metallic base achieves ideal cutting edges and provides unsurpassed cutting sharpness.

Taking a paradoxical approach to the conventional concept of strengthening powder steel,

we have achieved high hardness without sacrificing workability or durability

by strengthening the base material.

Highest sharpness brought about by outstanding hardness.

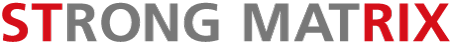

The hardness is about HRC65, the highest level of hardness for stainless steel for cutting tools, and, additionally, it demonstrates reliable cutting ability.

"Hardness of the metal base material" which engineers an unparalleled melding

of both ease of sharpening and sharpness.

SPG STRIX®

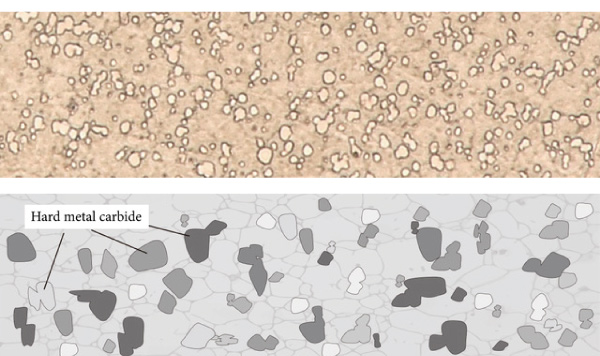

Conventional powder steel(Equiv. SKH40)

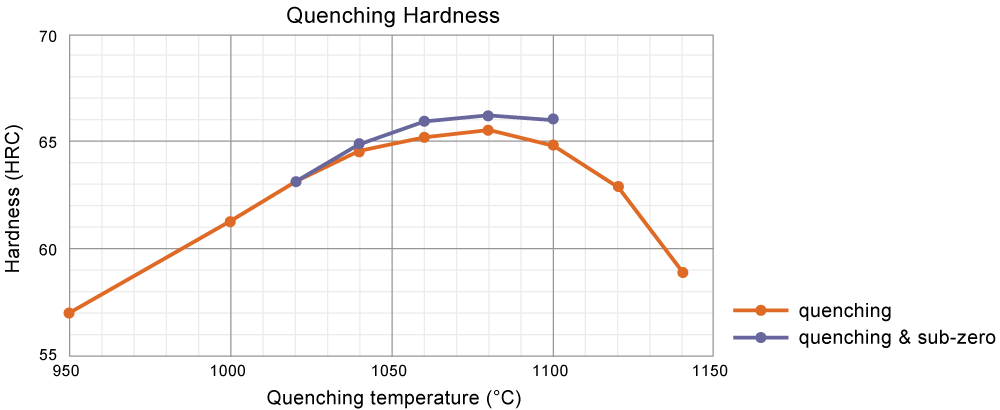

The hardness of a blade is the combination of "the hardness of the metallic base metal" + "the hardness of the metallic carbides".

Conventional powder steel is hardened by adding many elements and dispersing very hard metal carbide particles, such as vanadium carbides.

While hardness is achieved, the hard carbides make it difficult to sharpen because when they appear on the surface, they cause the grinding wheel to just slide along the surface, instead of grinding it into a fine and sharp edge.

SPG STRIX® achieves high hardness by hardening the metal base.

Even without the hard metal carbides of conventional powder steel, the hard metallic substrate and high average hardness of the metallurgical structure as a whole make it less susceptible to the effects of hard metal carbides during grinding, resulting in easy sharpening and excellent edge sharpness like that of carbon steel.

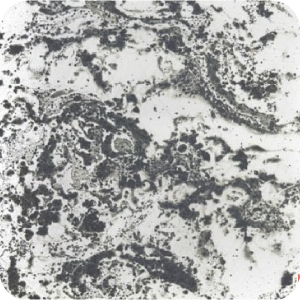

Excellent corrosion resistance even at high hardness

SPG STRIX®

Conventional powder steel(Equiv. SKH40)

Measured at 200mm² test specimen surface

Test conditions: 5% sodium chloride solution, 35°C, 75kPa, 24h continuous spray

Normally, there is a trade-off between corrosion resistance and hardness.

SPG STRIX® not only strengthens the base metal, but also provides a good balance of corrosion resistance, toughness, and other elements required for blades.

※The chemical composition values listed on this website are representative data for the standard values of each steel grade.