Rolling process

- Annealing and straightening

- Soft annealing

- Vacuum heat treatment

- Bright heat treatment

- Salt bath heat treatment

- Quenching and tempering

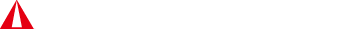

Our company is a metal rolling specialist that can perform integrated processing from hot rolling to cold rolling.

In addition to the various processes associated with rolling, we also offer customized solutions to address our customers’ needs.

Our metal rolling technique is unique in the industry.

Consigned Customized Processing 5 Strengths

Why customers choose us!

Processing Technologies

We offer exceptional processing technology that can only be achieved by a cladding manufacturer who has extensive expertise in all manner of metals. We propose processing methods that meet our customers’ high expectations and requirements.

Rolling process

- Annealing and straightening

- Soft annealing

- Vacuum heat treatment

- Bright heat treatment

- Salt bath heat treatment

- Quenching and tempering

Point!

The ability to perform integrated processing from hot rolling to cold rolling enables us to provide high quality, quick delivery, and high-cost performance processing.

We can propose a variety of rolling methods according to shape and material.

Heat treatment processing

- Annealing and straightening

- Soft annealing

- Vacuum heat treatment

- Bright heat treatment

- Salt bath heat treatment

- Quenching and tempering

Point!

Thorough control of the furnace temperature and flexible temperature condition setting enables us to provide high quality data and processed materials.

Cutting process

- Gas cutting - Leveling cutting

- Shear cutting - Wire cutting

- Saw cutting - Water jet cutting

- Laser cutting

- Slitter cutting

Point!

We propose the appropriate cutting method according to the material shape. We can handle a wide range of material sizes.

Surface treatment and Leveling

- Shot blasting

- Leveling

- Sand blasting

- Press straightening

- Acid pickling

Point!

We can propose the best method for post-processing with our wide variety of surface treatment facilities.

Cutting and polishing

- Buffing

- Surface grinding

- 5-axis machining center

- Milling cutter

- Lathing

Point!

Clad composites of different materials and molds can also be cut.

*Please don't hesitate to ask about material, processing details, and each conditions.

Rolling Process Achievements

We can even process materials that you may have thought impossible!

| Types of Metal | Materials |

|---|---|

| Stainless steel | Austenitic stainless steel (SUS303, SUS304, SUS316L, SUS310S, etc.), Martensitic stainless steel (SUS410, SUS403, SUS420J2, SUS440C, etc.), Ferritic stainless steel (SUS430, SUS405, etc.), SUS630, Duplex stainless steel, etc. |

| Steel, Carbon steel, Alloy, High-speed steel | SS400, S15S, S45C, SK, SKH, SKD, SCM, SUH, SUJ2, Bainite steel, maraging steel, high-strength steel, TRIP steel, Inver alloy |

| Metallic Element |

Copper (Cu), Aluminum (Al), Nickel (Ni), Titanium (Ti), Vanadium (V), Molybdenum (Mo), Silver (Ag), Chromium (Cr), Zirconium (Zr), Magnesium (Mg), Niobium (Nb), Manganese (Mn), We can also handle other metals. |

| Alloy metal (Available for development materials) |

Copper alloys (brass, chrome copper, phosphor bronze, aluminum bronze, etc.), Aluminum alloy (A2017, A3003, A4032, A5052, A6061, A7003, etc.), Nickel alloys (Cr-Ni alloys, Cr-Fe-Ni alloys, Cr-Mo-Ni alloys, Ni-Ti alloys, etc.), Titanium alloy (β titanium: 15-3-3-3, α + β titanium: 32 alloy, 64 alloy, etc.) We can also handle chrome alloys, zirconium alloys, magnesium alloys, niobium alloys, manganese alloys, silicon alloys, and other uniquely developed alloys. |

Custom Metal Processing Q&A

There is no material available with the thickness I need. This material matches my requirements but I need it just a little thinner.

Leave it to us! We can process the material to your desired thickness using our hot rolling and cold rolling facilities.

I would like to turn 10g of molten material into a metal plate for a prototype, but forging is difficult and time-consuming.

We can accept orders even as small as 10g!

In addition, and by consultation with our customer, we can produce metal sheets through rolling, even from irregularly shaped materials, such as thick rectangles, round bars, etc.

I want 500 mm width rolled sheets, but I can't find a place that can do the rolling...

We can perform hot rolling up to 420mm width and cold rolling up to 500mm width! There are only a few companies in Japan that can roll up to 500mm width in small lots, so please contact us.

Requests for rolling of hard and brittle materials are turned down by all companies. I wonder if there is a company that can do this.

We can also handle hard and brittle, difficult-to-process materials that fracture easily!

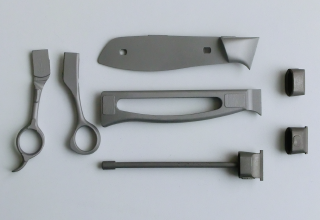

bolster for kitchen knife, handle cap,

scissors handle, machine parts, etc.

[annealed, shot surface]

material: CORELESS

CORELESS

Size: 5.5" 6.0" 6.5" 7.0"

cutting blade, shredding blade, round blade, solid steel products, brazing products, etc.

use : paper processing, recycle shredding, iron and steel processing, food processing, etc.

* We are taking another usual steel. Please don't hesitate to ask us details.